SAILING

By Bob Gray

September 2016

NEWPORT 16

I bought a Newport 16 sailboat in February of 1971.† I had fallen in love with sailing when I was in college.† A friend had a sailboat on the bay in Erie.† He asked me if I wanted to go out with him one summer evening and I said yes.† After spending a magical evening silently sailing around the Presque Isle Bay, I was hooked.† I had to wait to get my own boat until after I graduated from college and had saved enough money for one.† I saw an ad in the Washington Post for a boat dealer in Deale, Maryland.† The ad was for a used Newport 16. I thought it might be a good boat for me as I didnít know how to sail and the Newport 16 has a weighted (150 pounds) center board, making it a safe boat for a beginner.† The pictures below are of my boat at the Tri State Marine boatyard the day I bought it.†

†††††††††††††††††††††††††††

†††††††††††††††††††††††††††

My Newport 16 at the Tri State Marine Boatyard in Deale, Maryland.

As documented by others on the internet, the Newport 16 was

only made for a few years before its name was changed to the Baymaster 16.† Iím

pretty sure my boat was built in 1970. †Iím

quite certain I found a hull number on the underside of starboard cockpit bench

during a repair, but it must be further in than Iím willing to go at this stage

of life as I couldnít find it.† A fact

sheet for the Newport 16 is

available here and one for the Baymaster 16 is here.†

On the second page of the Newport 16 fact sheet are my calculations of

what the boat I bought cost new ($2,233).†

Iím pretty sure I paid $2,100 for the boat, trailer, and outboard motor.

Getting a motor (a McMar Commando 500, 5 hp, air cooled, two-stroke unit) with the boat wasnít much

of a deal as it proved to be very unreliable.†

I eventually left it at home and bought a second paddle for times of

little wind.

Modifications

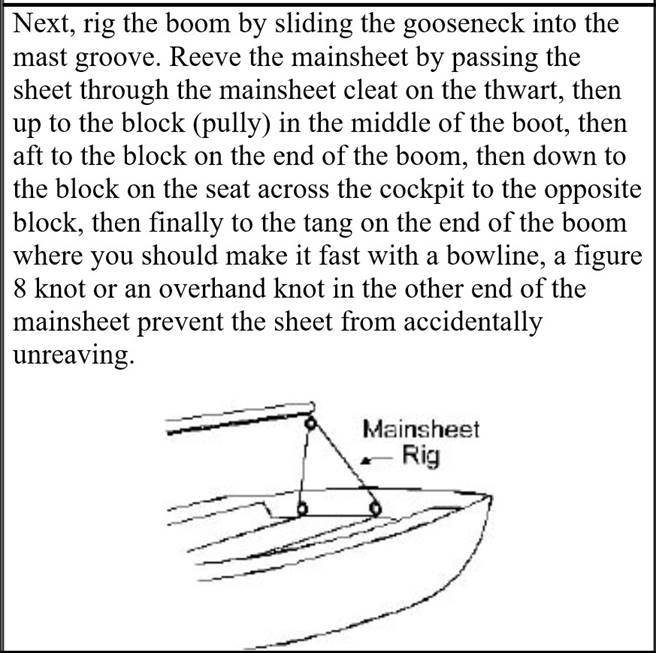

The original owner had made some modifications to the boat rigging including the addition of a swivel tackle for the main sheet that was mounted on the center board winch support instead of on the side of the cockpit.† An ownerís manual for the Newport 16 is available at Andrew Linnís web page (http://www.andrewlinn.com/sailboats/newport/manual/manual.htm). I didnít get a manual with my boat which is too bad as I had to puzzle through a lot the setup.† The instructions for rigging the main sheet are shown below.†

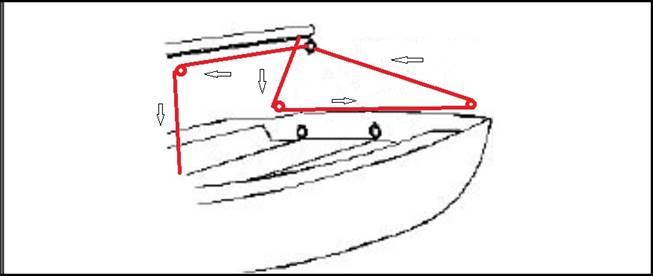

The cleat for the main sheet is on the side of port cockpit, which is not the most convenient placement.† The original owner mounted the swivel tackle block and cleat on top of the centerboard winch support and put another block on the boom directly over the tackle block.† Not knowing how they rigged the main sheet, I tried using one of the original cleats on the transom seen in the picture above.† This didnít work out to well as it made the position of the main asymmetrical.† I first tried moving the swivel block to the transom which made it too difficult to release quickly and finally settled on adding two new blocks on the transom, moving the swivel tackle block back to the centerboard winch support, and running the main sheet in a triangle at the transom and then forward to the swivel tackle block.† The figure below shows how the main sheet is now rigged.

The next thing I changed wasnít so much a modification as an adjustment.† I found that instead of heading into the wind when I left the tiller alone, the boat would actually fall off and pick up speed.† I investigated the problem and found that changing the tilt of the mast should help make the boat more neutral.† I moved the back stays of the mast downward to tilt the mast towards the stern which improved the balance.† In light air, the boat still drifts off instead of going into irons but it is definitely better than when I first started sailing.

The item that has received the most attention over the years is the winch for the weighted centerboard and its support structure.† The instructions and figure below are from the manual for the Newport 16.† Note the caution about keeping fingers and small children away from the winch mechanism.† This is good but insufficient advice as the centerboard weight 150 pounds and the winch has a relatively short handle so that it will clear the sides and bottom of the cockpit.† There is a lever on the winch that allows it to turn freely in one position and raises the centerboard in the other.† Lowering the centerboard requires placing the lever in the free while maintaining control of the crank.† During an early outing, my wife lost her grip on the centerboard winch crank handle and the centerboard went into a free fall until it hit the boot for the centerboard.† The crank handle contacted her hand in the process, making for a very painful sail that day.† In addition, the centerboard hit the fiberglass boot with such force that it cracked the hull in that area.† As our sail progressed, the boat took on enough water that it simply would not sail closer to the wind than a broad reach.† This made returning to the dock impossible and the outboard motor would not start.† I had to flag down a power boat and ask for a tow which they reluctantly provided as they couldnít understand why we could simply sail the boat back to the dock.† I repaired the damaged hull with fiberglass cloth and resin before our next outing.† Fortunately, the damage was at the bottom of the boot and easily accessed.†

The other difficulty with the centerboard winch mechanism is the fact that the angle of the wire cable changes as the board is raised or lowered.† The boat came with a brass fitting for the centerboard cable to pass through but it quickly became distorted and had to be removed.† Without the brass fitting, the cable would come in contact with the hull as it was raised or lowered, which in turn, caused the wire cable to fray or, worse, get stuck in the fiberglass.† So, in addition to needing to be careful not to let the crank handle slip, you also had to watch that you didnít come in contact with the cable, as the frayed strands would cut you.† Eventually, the fraying got so bad I decided to replace the cable.† This was not a simple job but I donít remember the specifics of how I accomplished it.† I replaced it with wire cable that had a plastic coating which I hoped would help with the fraying.† I also put in a new brass fitting but neither helped.† The other issue I had with the centerboard winch design was the fact that the pass through allowed a lot of water into the cockpit.† I used to put a cork in the fitting once the centerboard was lowered.† About five years ago, I decided to try and redo the whole winch mechanism.† I bought a new winch (Fulton brake winch) that had an internal brake mechanism that would allow the centerboard to be lowered without the risk of it free falling.† I opened up the hole in the deck so that the cable could pass through without coming in contact with the fiberglass.† As seen in the picture below, I mounted the winch vertically and opened up the pass through in the hull to allow the cable to be unobstructed.† I put plastic sweeps on each side of the hull pass through to keep the water out.† The main sheet swivel tackle is mounted on top of the winch support.† The location of the winch is less than ideal, as it is where I like to sit while sailing, but the ability to lower the centerboard without fear of losing a finger is a vast improvement over the original design.† I will most likely enclose the winch as I have discovered that my grandson is fascinated by the gears.

The new winch for the weighted centerboard has an internal clutch that

allows the centerboard to be lowered without fear of losing control of the

winch handle.

On the water

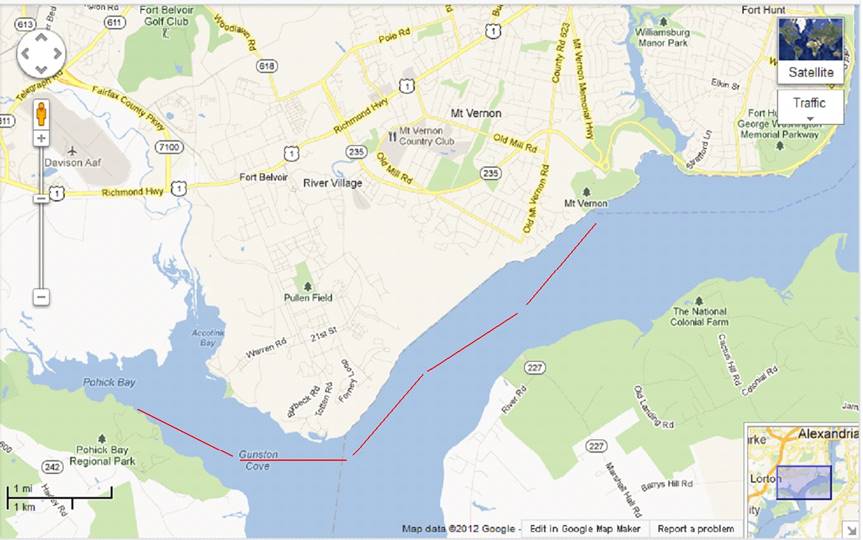

The following photographs cover the areas where I typically sail, Pohick Bay in Northern Virginia and Kerr Lake on the North Carolina - Virginia border.† They range from some of my earliest sails in 1971 to my most recent in August of 2016.†

Photograph c. 1971 published in the Potomac News.† On the boat with me are my wife, Mary-Alice,

and friend, Rich Kirchoffer.† Photograph taken at Pohick Bay State Park.

A good dayís sail is from Pohick Bay to Mount Vernon which about five

miles one way and might take two to three hours with favorable winds.

Photographs of the boat in Erie, Pennsylvania, July 1971.† We sailed in Presque Isle Bay but during the

day, not at night.

Leaving our campsite at County Line Park, Kerr Lake, North

Carolina.† Most likely in the spring of

1976. On the bow with paddle is Dan Spohn.† His daughter, Diana, and my daughter, Meghan,

are on my side of the cockpit. †My wife,

Mary-Alice, has her back to the camera.

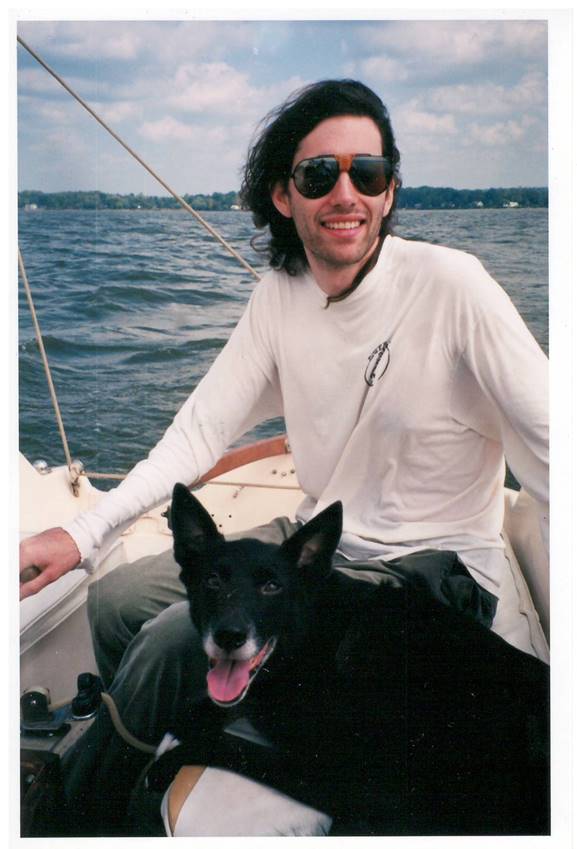

Sailing on the Potomac River, c 2005 with my son, Tyler, and Nico.

At the dock near Palmer Point State Park, Virginia, August 2016.

One of my favorite views: the Newportís sails

close hauled in a decent wind.

Coming into the dock at Kerr while my grandson, Keeghan,

watches, August 2016.

† Back to Hobbies | Home | Bob Gray Consulting | Lynch Gray family history | Genealogy

Copyright 2016, Robert F Gray